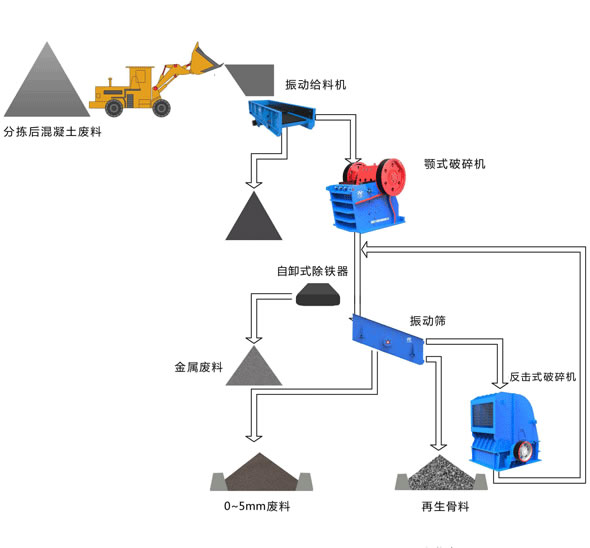

Production process and flow chart

The urban construction waste recycling process uses special equipment such as construction waste crushers, vibrating screens, and vibrating feeders to crush and screen construction waste to obtain recycled aggregates and reuse waste resources. The sorted construction waste undergoes specific iron removal equipment (dry magnetic separator) to remove the iron content contained in it, and is crushed by coarse crushing, medium crushing and even fine crushing equipment to be processed into a certain size of recycled sand and gravel aggregate , And finally used in roadbed stones, non-burning bricks, cement admixtures and many other aspects.

According to the production process of sand and gravel, the concrete, waste bricks, stones, etc. in the construction waste are processed and processed to realize resource reuse.

1. The first stage: convey the sorted concrete waste to the vibrating feeder, the feeder performs preliminary pre-screening, and the unnecessary waste is screened as necessary, and then evenly transported to the jaw crusher Crushing to obtain semi-finished aggregates;

2. Transport the semi-finished aggregate obtained in the first stage to the vibrating screen for screening to obtain waste of about 0-5 mm. The regenerated semi-finished material after screening is transported to the impact crusher for secondary crushing, and the cycle is repeated until Obtain the finished recycled aggregate required by users.